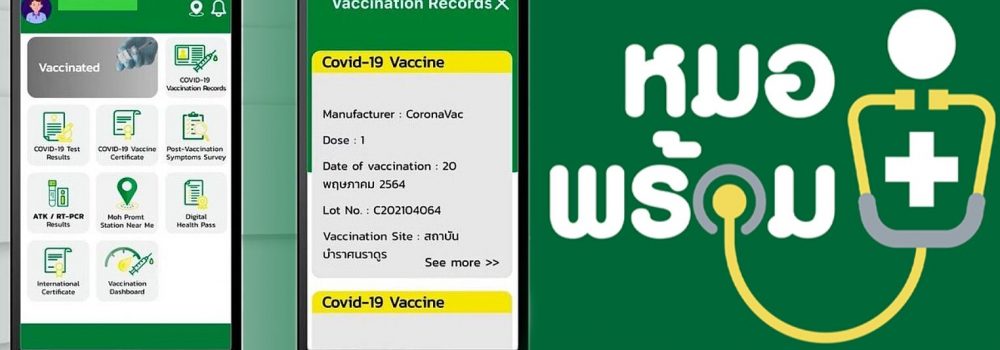

The Mor Prom mobile application, which was originally designed to track Covid cases, is being transformed into a national online health platform. The app has grown in popularity and now has 32 million users.

The Ministry of Public Health is working with private companies to transform Thailand’s national digital health platform, Mor Prom, into a mobile application. The updated app will provide Thais with a convenient and easily accessible health platform that includes 12 new features.

The app was initially designed for COVID-19 case tracing and registering people for Covid vaccination appointments. The new features will transform the app into a platform that connects to drug stores and a plethora of other public health service units. Approximately 15,000 service units and drug stores are currently linked to the app.

The security of the new Mor Prom app will adhere to worldwide safety requirements for electronic transactions and health information. This component is supported by the National Cyber Security Agency and the Electronic Transactions Development Agency.

The first of the twelve new capabilities are the COVID-19 vaccination certification service, which displays a traveller’s immunization record. The second function displays Covid test results obtained by the ATK and PCR techniques.

The third function allows users to search for a Covid testing unit near them, and the fourth feature enables site check-ins through a “beacon” mechanism. A digital health certificate display, money, organ donation services, a chatbot feature, and information on health policies are further features. Health history display, health appointment scheduling, health insurance policy verification, and telemedicine are the remaining features. The app will begin to receive additional functionality in August and September.

In the meantime, the collaboration between the National Science and Technology Development Agency (NSTDA) and the Electricity Generating Authority of Thailand (EGAT) marks a new milestone in the nation’s EV industry, as EV chargers are a vital part of the EV ecosystem.

The test ensured that the equipment used to service electric cars for both land and water transportation was safe. The test technique is based on the IEC 61851 standard for conductive charging systems for electric vehicles.

For electric buses, electric tractors, and electric ferries, the laboratory enables the testing of high-power DC chargers up to 150 kW. The availability of testing services in Thailand will significantly increase the competitiveness of local manufacturers, as they will no longer need to obtain testing and certification services from outside, hence reducing operating costs and development time.

In addition to EV charger testing, PTEC provides a variety of testing services to help the EV sector, including testing of lithium batteries, electric motorcycle battery modules, EV battery packs, electrification efficiency testing of electric motorcycles, and EV EMC testing.

Furthermore, for the sugarcane production industry, “Field Practice Solutions” (FPS) was developed as a precision agriculture system. FPS utilises drone footage for plantation area measurement, crop health monitoring, and weed/disease detection.

In addition, the system employs data processing to aid users in making educated decisions and effectively managing plantations, including fertilizer/chemical application and harvest schedules. NSTDA managed the public-private cooperation that led to the development of FPS.

On the other hand, the team created a data analytics system to estimate Brix content in sugarcane fields by combining multispectral images captured by drones with weather and sugarcane physiological data. With data on Brix and yield prediction, crops can be picked at the optimal moment for the most yield at the lowest cost.

With FPS, a harvest schedule may be properly scheduled to ensure that sugar mills receive sugarcane of optimal quality and quantity. This method has the potential to lower sugar production expenses by 20 per cent, or approximately THB 50 million per sugar mill annually.